Introducing the P9-80 Piston Pump: Unleash the Power of Fluid Control

Are you in search of a piston pump that combines strength, performance, and versatility? Look no further than the P9-80 Piston Pump. With its high strength cast iron body, high-performance sealing capabilities, and flexible inlet/outlet port positions, this exceptional pump is designed to revolutionize your fluid control operations. Join us as we delve into the remarkable features and benefits of the P9-80 Piston Pump.

Unparalleled Strength with a Cast Iron Body The P9-80 Piston Pump boasts a high strength cast iron body, ensuring exceptional durability and reliability even in demanding environments. This robust construction guarantees a long lifespan, allowing you to tackle fluid control tasks with confidence. Experience the power of a pump built to endure.

High-Performance Sealing for Optimal Functionality With its high-performance sealing capabilities, the P9-80 Piston Pump ensures leak-free operation, maintaining consistent fluid control. Its sealing materials are designed to withstand a wide temperature range, from -20°C to +120°C, enabling reliable performance in various operating conditions. Trust in the P9-80 Piston Pump to handle the heat and deliver precise fluid control.

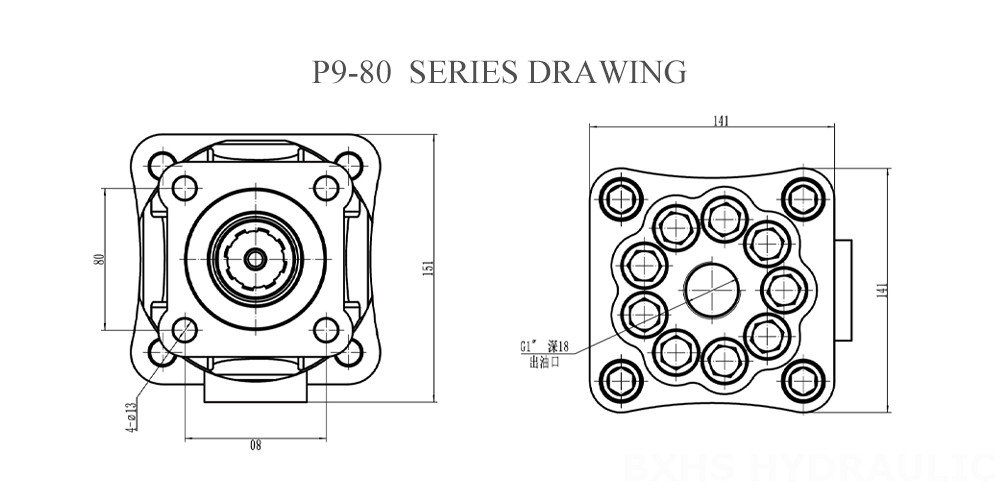

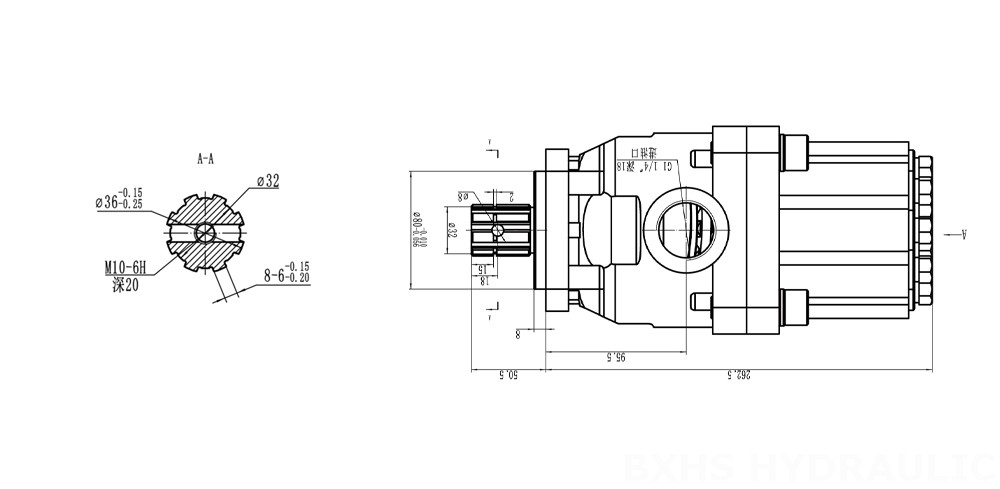

Flexible Inlet Shaft and Port Positions The P9-80 Piston Pump offers versatility with two kinds of rectangle spline options for the inlet shaft. This flexibility allows you to customize the pump to fit your specific requirements. Moreover, the pump offers multiple inlet/outlet port positions, including side in side out, side in bottom out, bottom in bottom out, and more. Enjoy the convenience of configuring the pump according to your fluid control needs.

Unleash the Power of Fluid Control Equip yourself with the P9-80 Piston Pump and experience the next level of fluid control performance. Its high strength cast iron body ensures durability, while the high-performance sealing guarantees leak-free operation in extreme temperatures. With flexible inlet shaft and port positions, this pump adapts to your unique requirements. Don’t settle for anything less than precise and reliable fluid control. Choose the P9-80 Piston Pump and unleash the power of fluid control.

Piston Pump User Manual

Technical Specifications

- Rated Pressure: 25 MPa, Maximum Instantaneous Pressure: 28.5 MPa.

- Rated Speed: 1200 r/min, Minimum Speed: 300 r/min, Maximum Speed: 1500 r/min.

- Rotation Direction: Bidirectional.

- Displacement: 100 mL/r.

Installation Precautions

- The hydraulic oil used should be clean, free from impurities and corrosive substances. Recommended oil type is L-HM46 (GB11118.1-94).

- The oil level in the hydraulic oil tank must be at least 0.5m higher than the inlet of the piston pump during installation.

- During installation, ensure that the piston pump inlet is filled with hydraulic oil.

- It is recommended to install the piston pump with the inlet facing upwards or towards the sides. Installing with the inlet facing downwards is not recommended, as it may trap air in the pump body, leading to the pump not being able to draw oil.

- The inlet and outlet pipes of the piston pump should be securely fastened and effectively sealed to prevent air suction or oil leakage, which may affect its performance.

- During installation, measure whether the effective depth of the internal spline exceeds the axial extension length of the piston pump to prevent shaft jamming.

- The maximum speed and pressure of the piston pump refer to the peak values allowed for a short period of time during use. Prolonged usage at these levels should be avoided to prevent affecting the lifespan of the piston pump.

- The hydraulic system should have a filtering device with a precision of less than 25 μm. The filtering device should be installed at the outlet, and using a filtering device at the inlet is not recommended as it may affect the pump’s oil suction.