Showing 1–18 of 262 results

10.5 GPM 2 Spool Joystick Directional Valve with P40 Micro Switch – Global Hydraulics Manufacturer & Supplier

In stock

| Weight | 5.60 kg |

|---|---|

| Dimensions | 33 × 18 × 17 cm |

| Control Method |

joystick |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

2 Spool |

| Product Model |

P40 Micro Switch Joystick |

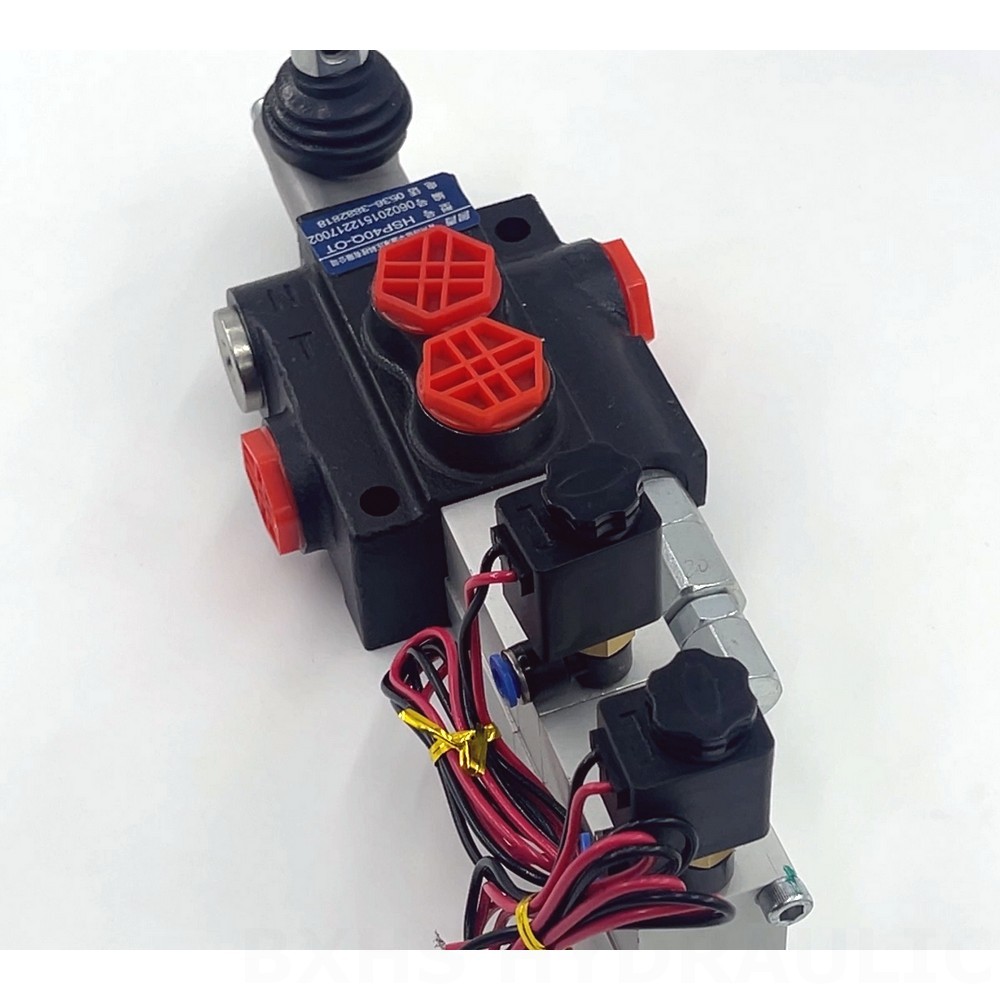

10.5 GPM 2-Spool Electro-Hydraulic Directional Valve (P40) – Manufacturer, Distributor & Wholesale Opportunities

In stock

| Weight | 9.30 kg |

|---|---|

| Dimensions | 31 × 18 × 17 cm |

| Control Method |

electro-hydraulic |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

2 Spool |

| Product Model |

P40 Electro-hydraulic |

10.5 GPM 2-Spool Monoblock Directional Valve (P40 Floating) – Global Supplier for Manufacturing, OEM & Distribution

In stock

| Weight | 4.70 kg |

|---|---|

| Dimensions | 19 × 31 × 12 cm |

| Control Method |

cable |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

2 Spool |

| Product Model |

P40 Floating Cable |

10.5 GPM 2-Spool Pneumatic Directional Valve (P40) – Manufacturer, Supplier & Distributor

In stock

| Weight | 5.70 kg |

|---|---|

| Dimensions | 23 × 18 × 13 cm |

| Control Method |

pneumatic |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

2 Spool |

| Product Model |

P40 Pneumatic |

10.5 GPM 2-Spool Solenoid Directional Valve (SD5) – Manufacturer, Supplier & Distributor

In stock

| Weight | 7.00 kg |

|---|---|

| Dimensions | 30 × 18 × 15 cm |

| Control Method |

solenoid |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

315 bar (31.5 MPa) |

| Spool |

2 Spool |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Product model |

SD5 Solenoid |

10.5 GPM 2-Spool Solenoid Monoblock Directional Valve (P40) – Manufacturer & Distributor

In stock

| Weight | 6.20 kg |

|---|---|

| Dimensions | 30 × 18 × 12 cm |

| Control Method |

solenoid |

| Section |

2 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

2 Spool |

| Product Model |

P40 Solenoid |

10.5 GPM 3-Spool Manual Directional Valve (P40) – Global Supplier, OEM & Custom Manufacturing

In stock

| Weight | 6.60 kg |

|---|---|

| Dimensions | 23 × 20 × 12 cm |

| Control Method |

manual |

| Section |

3 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

3 Spool |

| Product Model |

P40 Manual |

10.5 GPM 3-Spool Solenoid Directional Valve (SD5) – Manufacturer, Distributor & OEM Services Available

In stock

| Weight | 8.60 kg |

|---|---|

| Dimensions | 30 × 21 × 13 cm |

| Control Method |

solenoid |

| Section |

3 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

315 bar (31.5 MPa) |

| Spool |

3 Spool |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Product model |

SD5 Solenoid |

10.5 GPM 4-Spool Electro-Hydraulic Directional Valves: Manufacturing, OEM, & Distribution

In stock

| Weight | 16.50 kg |

|---|---|

| Dimensions | 31 × 24 × 17 cm |

| Control Method |

electro-hydraulic |

| Section |

4 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

4 Spool |

| Product Model |

P40 Electro-hydraulic |

10.5 GPM Electro-pneumatic Directional Valve (P40) – Global Manufacturer, Distributor & OEM Services

In stock

| Weight | 3.56 kg |

|---|---|

| Dimensions | 13 × 20 × 12 cm |

| Control Method |

electric proportional |

| Section |

1 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

1 Spool |

| Product Model |

P40 Electro-pneumatic |

10.5 GPM Hydraulic Monoblock Directional Valve (SD4) – Global Manufacturer & Distributor

In stock

| Weight | 2.50 kg |

|---|---|

| Dimensions | 13 × 22 × 13 cm |

| Control Method |

manual |

| Section |

1 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

250 bar (25 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

1 Spool |

| Product Model |

SD4 Manual |

10.5 GPM Pneumatic Control Valve (BKQF34-A) – Manufacturing, Private Labeling, and Global Distribution

In stock

| Weight | 0.40 kg |

|---|---|

| Dimensions | 23 × 10 × 8 cm |

| Control Method |

manual |

| Section |

1 Section |

| Structure Type |

Monoblock valve |

| Rated Flow |

40 L/min (10.5 US gpm) |

| Max Pressure |

1 MPa (145 psi) |

| Operating Viscosity Range |

12 – 400 mm²/s (12 cSt to 400 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| spool |

1 Spool |

| Product model |

BKQF34-A Manual |

13.2 GPM 5-Spool Solenoid Valve HDCF50: Manufacturer, Supplier & Distributor of Hydraulic Components

In stock

| Weight | 19.50 kg |

|---|---|

| Dimensions | 40 × 35 × 20 cm |

| Control Method |

solenoid |

| Section |

5 Section |

| Structure Type |

Sectional valve |

| Rated Flow |

50 L/min (13.2 gpm) |

| Max Pressure |

160 bar (2300 psi) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-20°C to +80°C (-4°F to +176°F) |

| Spool |

5 Spool |

| Product Model |

HDCF50 Solenoid |

| Voltage |

12V 24V |

13.2 GPM 6-Spool Solenoid Valve HDCF50: Manufacturer, Supplier & Distributor of Hydraulic Valves

In stock

| Weight | 24.50 kg |

|---|---|

| Dimensions | 36 × 22 × 26 cm |

| Control Method |

solenoid |

| Section |

6 Section |

| Structure Type |

Sectional valve |

| Rated Flow |

50 L/min (13.2 gpm) |

| Max Pressure |

160 bar (2300 psi) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-20°C to +80°C (-4°F to +176°F) |

| Spool |

6 Spool |

| Product Model |

HDCF50 Solenoid |

| Voltage |

12V 24V |

13.2 GPM Hydraulic Flow Diverter Valve (HSV06) – Manufacturing, Private Label, & Global Distribution

In stock

| Weight | 3.10 kg |

|---|---|

| Dimensions | 23 × 15 × 12 cm |

| Control Method |

solenoid |

| Section |

1 Section |

| Structure Type |

Sectional valve |

| Rated Flow |

50 L/min (13.2 gpm) |

| Max Pressure |

180 bar (2600 psi) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-20°C to +80°C (-4°F to +176°F) |

| Spool |

1 Spool |

| Product Model |

HSV06 Solenoid |

15.8 GPM 3 Spool Hydraulic Directional Valve (DCV60) – Global Manufacturer & Distributor

In stock

| Weight | 18.30 kg |

|---|---|

| Dimensions | 29 × 35 × 17 cm |

| Control Method |

cable |

| Section |

3 Section |

| Structure Type |

Sectional valve |

| Rated Flow |

60 L/min (15.8 US gpm) |

| Max Pressure |

350 bar (35 MPa) |

| Operating Viscosity Range |

15 – 75 mm²/s (15 cSt to 75 cSt) |

| Ambient Temperature Range |

-40°C to +80°C (-40°F to +176°F) |

| Spool |

3 Spool |

| Product Model |

DCV60 Cable |

Recently Viewed Products

Our Products and Services

Here's what we can do

Our main products include Directional Control Valves, Gear Pumps, Steering Equipment, and Power Units, with over 500 models that are widely used in various industries such as construction, sanitation, drilling, and mining. In addition to our standard product offerings, we also support OEM/ODM services, allowing us to customize hydraulic products according to our customers' specific needs and requirements. Our professional R&D team and advanced production technology ensure the quality and timely delivery of our products, while our comprehensive pre-sales and after-sales services help our customers improve their product competitiveness.